While discussions of HVAC (Heating, Ventilation, and Air Conditioning) upgrades often revolve around major investments like replacing furnaces or chillers, there’s a key player that often flies under the radar – the control valve. These deceptively simple devices have surprising power over a system’s overall efficiency and performance. Outdated or worn control valves can hinder comfort levels and lead to unseen energy waste. This article sheds light on why considering upgrading to Honeywell control valves might be more worthwhile than you think.

The Vital Role of HVAC Control Valves

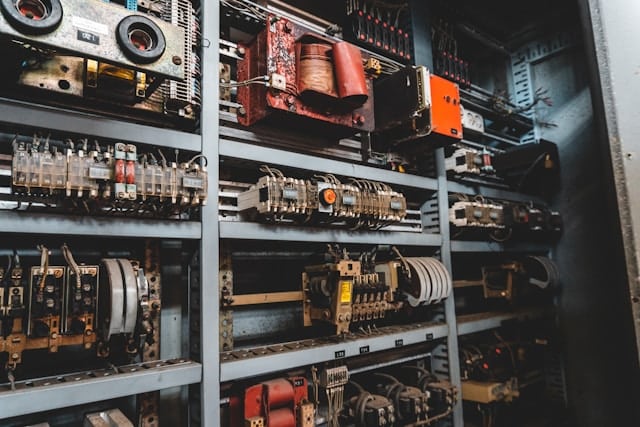

Picture your HVAC system as a network of pipes carrying fluids. Control valves act like smart traffic lights or gates within this network. They open, close, or partially obstruct these pathways to control the flow of hot water, chilled water, or other working fluids. This regulation is crucial for maintaining consistent temperatures within a building, delivering desired heating or cooling, and directly influencing how hard your HVAC equipment works.

There are various control valve types with specialized functions:

- Two-way valves: The most common type, providing basic on/off control or simple flow adjustment.

- Three-way valves: Enable mixing or diverting flows, useful for managing temperature zones.

- Other specific valve types: Examples include pressure-reducing and balancing valves for maintaining system stability.

Why Upgrade? The Case for Modernizing Control Valves

Upgrading to more advanced KMC control valves is like trading in an old manual thermostat for a smart programmable one. Here’s why many savvy building owners are now taking this step:

- Leaps in Efficiency: Older valves often lack precision, leading to overshooting or undershooting temperatures and wasted energy. Newer models with more refined accuracy ensure greater heating/cooling efficiency, which quickly translates to savings on energy bills.

- Comfort and Consistency: Upgraded valves help eliminate the uncomfortable hot and cold swings within a space by carefully regulating the supply of chilled or hot water. This means the HVAC system delivers what you demand, providing greater overall comfort.

- Lighter Maintenance Load: Modern, well-engineered valves tend to be more robust and less prone to leaks or malfunctions compared to their aging counterparts. This streamlines maintenance, cuts downtime, and minimizes potential operational headaches.

Benefits Beyond Efficiency

The case for upgrading your HVAC control valves doesn’t just revolve around immediate energy savings. The advantages include:

- Equipment Preservation: Outdated or ill-performing valves can subtly strain your HVAC system. Precision control provided by modern valves reduces wear and tear on components like boilers, chillers, and pumps, potentially extending their lifespan.

- Fewer Leaks and Issues: Leaks at old valve connections or around seals not only impact comfort but waste water and energy. High-quality valves are precision-engineered to minimize these occurrences, saving you headaches and unnecessary emergency maintenance calls.

- Smarter Diagnostics: Many modern control valves integrate seamlessly with Building Automation Systems (BAS). They not only regulate flow but provide valuable data points on temperatures, pressure variations, and other indicators that alert operators to potential problems far before they escalate.

Choosing the Right Technology

Embarking on a control valve upgrade means navigating some choices. Here’s a deeper dive to help you determine what best suits your project:

- Compatibility: Your existing HVAC system is always the starting point. New valves must not only be compatible with the type of fluid they’ll manage but also factors like pipe sizing and your system’s overall flow characteristics. An HVAC professional can ensure correct selection.

- Features and Precision: How sensitive does your temperature control need to be? Basic valves provide on/off or broad throttling. For applications like hydronic heating in hospitals or process control applications, finer temperature control translates to significant energy savings and process control precision. Opt for a valve with the accuracy level your situation demands.

- Brands: Several industry leaders like Belimo, Honeywell, KMC and Siemens control valves offer diverse product lines. Research product ranges and features carefully to match your needs and budget.

- Beyond Reliability: Do downtime and malfunctions negatively impact your operation? Some modern valve technologies with built-in diagnostic sensors and predictive failure warnings could be more than a convenience. They translate to proactive maintenance that protects both your HVAC equipment and avoids disruptions to your building or the services it provides.

- Basic vs. Smart: Need reliable flow control at the most economical price? Classic valves might suffice. For integration with a Building Automation System (BAS) or remote management capabilities, “smart” valves tailored for this connectivity are the way to go.

Integration and Automation Possibilities

Upgrading to valves designed for BAS (Building Automation Systems) unlocks significant benefits:

- Automated Comfort: Link your valves to the building’s smart management system for dynamic temperature control via schedules or adaptive learning algorithms. This takes the manual tweaking out of comfort provision.

- Remote Control and Oversight: Keep an eye on valve settings and operation through remote dashboards accessible from anywhere with an internet connection. This can be exceptionally useful for multi-property owners or businesses with several locations.

- Beyond Thermostats: Integrating valve data reveals patterns and inefficiencies your thermostats alone wouldn’t catch. These insights help streamline overall operation and make proactive interventions before occupants even feel the difference.

Is the Investment Worth It?

Determining if getting a Belimo control valves upgrade makes financial sense requires a little number crunching:

- Upfront Costs vs. Potential Savings: Factor in potential energy savings based on your building’s size and system usage. Don’t forget the reduced labor and headache savings due to a smoother-running, more dependable system with fewer breakdowns.

- Future-Proof Thinking: Many buildings now adopt a strategy of incremental upgrades instead of monolithic overhauls. Upgrading valves could put you in a better position for future system optimization and integration with cutting-edge automation technologies.

- Sustainability Wins: Reduced energy demand thanks to precision control contributes directly to minimizing your building’s environmental footprint.

Conclusion

HVAC control valves may not be the flashiest aspect of your building, but when outdated, they quietly sabotage both your bottom line and comfort levels. Modern, high-performance valves optimize the way your system functions, delivering superior temperature control, reducing energy expenditure, and extending the life of costly HVAC equipment. While they don’t entirely replace major equipment upgrades, rethinking this oft-neglected part of the system could offer far greater returns than expected.

This upgrade journey begins with consulting an HVAC professional for an assessment of your current system and a tailored control valve solution to fit your specific needs.

Comments are closed.